This Notebook covers several historical threads, each of which should probably have its own treatment. But as I know little about them and have so far been unable to untangle them, I'll cover them all here. The earliest machine associated with these threads of technological history dates to the 1880s, while the latest is still being manufactured. This line of machines is also directly associated with the best known name in type in the 20th century, Frederic Goudy. This has turned into a very long page, but it is easy to search and it's useful to have everything in one place.

So here are machines associated in some way with William S. Eaton. These include:

This present Notebook is simply a dump of everything I could discover about these machines. It isn't going to win any awards for style or clarity. But this subject has been so unreasonably obscure, and its relevance to Goudy so important, that it seemed best to present everything.

Things go back at least as far as Stephen Decatur Engle (1837-12-18 to 1921-01-21) of Luzerne County, Pennsylvania. He was a farmer and watchmaker, and his many inventions included a pantograph. [His dates and full middle name I found in an online genealogical search; I have not yet verified them.]

US Patent 246,737 (Stephen D. Engle, 1881)

US patent 246,737, "Pantograph Engraving Machine." Issued 1881-09-06 to Stephen D. Engle. Filed 1881-04-22 (no application serial number given).

This is not a rotary or a drag engraving machine. Rather, it was designed either to guide a pencil or, when engraving in metal, to guide a single-point cutting tool in partial mechanization of hand-engraving techniques. In this latter case, the orientation of the tool and tracer were to be coordinated by a chain-and-sprocket arrangement. (For another example of this kind of machine, see the Francis.)

US Patent 275,618 (Stephen D. Engle, 1883)

US patent 275,618, "Engraving Machine." Issued 1883-04-10 to Stephen D. Engle. Filed 1882-11-22 (no application serial number given). A drag engraver similar to his 1881 machine, but with no optional provision for guiding the engraving cutter. The cutter's form is specified as a half-cone. I like the swans' heads cast into the frame - a nice touch.

Popular Science (1891)

The Engle machine substantially as described in his 1883 US patent 275,618 (see above) is shown in an article by C. Hanford Henderson, "Glass-Making. Part V. Glass in Science" in Popular Science Monthly, Vol. 39, No. 5 (September, 1891): 629-633. Note the ornamental swans' heads.

The icon at left links to the presentation at The Internet Archive of the scan of this volume done by the Woods Hole Marine Biological Laboratory of their library's copy. You can read it online there, or download it in a variety of formats (from PDF and DjVu (nicer) to the (large) original scans). For no particularly good reason, here is a PDF of just the Henderson article, extracted from the PDF version. The PDF version (and this extract) suffer greatly in image quality when compared to the original JP2 scans and the DjVu version; it's useful mostly for the text. popular-science-monthly-v039-n5-1891-09-archive-org-woods-hole-popularsciencemo39newy-pp611-633-img629-651.pdf

(The image above links to a 1024 pixel wide JPEG version rendered and cropped from the original scan. It's sufficient for most viewing. Here is a full-available-resolution PNG version (rendered and cropped from the original, 9 Megabytes): popular-science-monthly-v039-n5-1891-09-archive-org-woods-hole-popularsciencemo39newy-p629-img0647-render-JP2toPNG-crop-1784x2556.png Here is the original JP2 (JPEG 2000) page scan, without any further processing at all (1 Megabyte): popular-science-monthly-v039-n5-1891-09-archive-org-woods-hole-popularsciencemo39newy-p629-img0647.jp2 Note that at the time of writing (2013), were over a decade into the 21st century and most web browsers still can't handle JPEG 2000. You only want to trouble yourself with the JP2 version if you know how to handle it.)

The Stephen D. Engle machine is a vertically arranged pantograph with a non-rotary engraving tool. It is in many ways quite similar to the Eaton-Engle machine as later manufactured. It was modified by William S. Eaton and William T. Goodnow (whose mother-in-law was an Engle) in US patent 585,261 (1897), assigned to the Eaton-Glover company (manufacturers of the Eaton-Engle).

Stephen Engle seems to have been quite an interesting character. Here is a sketch of his life from a local county history.

Stephen D. Engle

Bradsby, H. C., ed. History of Luzerne County Pennsylvania with Biographical Selections. (Chicago: S. B. Nelson & Co., 1893). Extract of Volume 2, pp. 874-875 concerning Stephen D. Engle.

As noted elsewhere in this Notebook William T. Goodnow co-patented the improvements on the Engle pantograph when it was manufactured as the Eaton-Engle.

The 1920 US Census lists a William T. Goodnow, born about 1863, as then being in Bradford, PA.

The 1885 Lehigh University yearbook lists William T. Goodnow as a senior.

But The Lehigh Burr, Vol. 16, No. 6 (January 19, 1897), p. 65, lists W.T.Goodnow as a member of the class of '83. This entry is also useful because it gives his position as the "general manager of the Cayuta Wheel and Foundry Company" (which was located in Sayre, PA, and which, according to several contemporary trade sources, had an output of 70,000 railway wheels per year).

The journal The Foundry, Volume 23, No. 3, WHole No. 135 (November, 1903), p. 122, lists William T. Goodnow as a director of the newly consolidated National Car Wheel Co., of Rochester, NY. His involvement was certainly through the Cayuta Wheel & Foundry Co. of Sayre, PA (one of the four firms consolidated into the National Car Wheel Co.) Here is the summary of the consolidation of this company, as listed in The Manual of Statistics: Stock Exchange Hand-Book Vol. 28 (1906):

In 1910, William T. Goodnow co-invented a lifting jack with Christian E. Loetzer (also of Sayre, PA). US patent 971,286.

The Alphabetical List of Charters of Corporations Enrolled in the Office of the Secretary of the Commonwealth [of Pennsylvania] During the Two Years Beginning June 1, 1917, and Ending May 31, 1919 lists William T. Goodnow as a director of both the Athens Borough Water Company and the Athens Township Water Company, both of Sayre, PA (incorporated May 16, 1918). (n.b., Google has digitized the University of California copy of this, which binds this volume together with volumes from 1913-1915 and 1915-1917; it lists it under the year 1915.)

An interesting biographical sketch of one Henry Dryfoos,Jr. appears in Historic Homes and Institutions and Genealogical and Personal Memoirs of the Lehigh Valley Pennsylvania Vol. II. (NY: The Lewis Publishing Co., 1905). This sketch notes, among other things, that his father, Henry Dryfoos Sr. (born in "Germany"; emigrated in 1857 or 1858) married "Mrs. D. Sloan, nee Sarah J. Engle, daughter of John Engle, a prominant resident of Lehigh Valley. Their Children are: Rose E., wife of W. T. Goodnow, of Sayre, Pennsylvania, ... and Henry Dryfoos, Jr." It also notes that Dryfoos, Jr. "is also largely interested in the Sayre Stamping Company, one of the leading industries of Sayre, Pennsylvania, and which he is serving in the capacity of vice-president; and is a director of the Eaton & Glover Company, manufacturers of engraving machines of New York City." (p. 348)

So it would appear that there were close family ties between Goodnow, Dryfoos, and the Engles (all from Pennsylvania), and business ties between all of them and Eaton and Glover (in NY).

I have not yet properly documented the date of birth of William Sylvester Eaton. Various online art auction sites (he painted landscapes in his later years) list it as 1861 or 1862; this seems approximately correct.

The Sag-Harbor Express for Thursday Morning, September 26, 1895, carried the following note:

"Eaton - William S. Eaton, superintendent of the Engraving Department in the Watchcase Factory, is soon to leave that institution, and go to LaFayette Collee at Easton, Penn., to perfect himself in Chemistry and metallurgy, after which he will return to Sag-Harbor."

(This newspaper has been digitized by Tom Tryniski and is available on his "Old Fulton NY Post Card" website at: http://fultonhistory.com/ )

The watchcase factory in Sag Harbor was that of Joseph Fahys & Co., one of the more important US watchcase manufacturers. Eaton would have been about 34 at the time he went off to college in Pennsylvania. While LaFayette College is in Easton (not Sayre) Pennsylvania, this move put him in the same general area as the Engles and Goodnow. Eaton's and Goodnow's patent 585,261, improving on Engle's machine and creating, basically, the Eaton-Engle machine, was filed only one year later, in 1896.

In his article on "Fahys of Sag Harbor, New York" (Part 1) NAWCC Bulletin No. 332 (June 2001): 316-324, John H. Wilterding Jr. identifies "Wm. S. Eaton: Head engraver at Fahys Watch Case Company and inventor of engraving tools and watch-making machinery. With capital of $7,000 he started his own dial works for watches and clocks. In 1913 he invented the Rotary Photogravure process that will be remembered by many readers as used for the Sunday newspapers and magazines." Wilterding cites as his source Aleson Cornish, et. al., Survey of Sag Harbor: A Report and Survey of the Historic Resources of the Village of Sag Harbor Volume 1. [No location, publisher, or date cited] I have not been able to verify Eaton's role in the development of rotary photogravure. He did patent a rotary intaglio printing press in 1915 (filed 1912), US 1,147,152, but that was assigned to the American Bank Note Company, who published few Sunday newspapers.

Eaton seemed (as far as the patent record shows) to have been interested primarily in aspects of multiple engraving during the late 1880s and early 1890s - either in building up single images from multiple originals or in engraving multiple copies simultaneously. His target markets seem to have been the watch and watch-case industries. In most of these inventions, insofar as pantographs might have been involved, they were indicated in the patents in only their most theoretical form.

(See also the note later about description by Francis Kisner of the composite patterns and shading devices used with the New Century.)

US Patent 402,314 (Eaton, 1889)

US patent 402,314, "Art of Engraving." Issued 1889-04-30 to William S. Eaton. Filed 1888-12-28 as application serial number 294,846. Composite designs.

US Patent 545,624 (Eaton, 1895)

US patent 545,624, "Method of Designing." Issued 1895-09-03 to William S. Eaton. Filed 1895-04-17 as application serial number 546,089. Designs in sections on a rotatable pattern plate.

US Patent 573,967 (Eaton, 1896)

US patent 573,967, "Art of Engraving." Issued 1896-12-29 to William S. Eaton. Filed 1896-01-09 as application serial number 574,894. Using stencils and pattern plates for shading effects.

US Patent 584,335 (Eaton, 1897)

US patent 584,335, "Engraving and Ornamenting Machine." Issued 1897-06-15 to William S. Eaton. Filed 1896-02-14 as application serial number 579,233. A multiple-engraving pantograph primarily employing rotary cutters (though the drag method is not excluded). It does not appear to be related either to Engle's earlier machine or to the later Eaton-Engle machine.

I'm going to break chronology and include Eaton's other "art of engraving" patents here. By 1896, though, he had begun working directly on the design of pantograph engraving machines.

US Patent 584,761 (Eaton, 1897)

US patent 584,7612, "Art of Designing and Engraving." Issued 1897-06-15 to William S. Eaton. Filed 1896-10-31 as application serial number 610,662. Compound monograms.

US Patent 588,558 (Eaton, 1897)

US patent 588,558, "Art of Engraving." Issued 1897-08-24 to William S. Eaton. Filed 1896-11-09 as application serial number 611,525. References US 402,314. Also references the patent filed as application s/n 574,894; this was issued as US 573,967. (For both, see above.) The use of transparent patterning plates (for shading effects) which, by virtue of their transparency, allow the operator to observe the work in progress and vary the pressure of the engraving tool so as to provide different effects.

US Patent 648,396 (Eaton, 1900)

US patent 648,396, "Ruling Attachment for Engraving Machines." Issued 1900-05-01 to William S. Eaton. Filed 1899-12-06 as application serial number 739,332. Cites as machines to which it might be applied Eaton's patents 584,335 (multiple engraving machine; see above) and 585,261 (Eaton and Goodnow; see below).

US Patent 585,261 (Eaton & Goodnow, 1897)

US patent 585,261, "Engraving-Machine." Issued 1897-06-29 to William S. Eaton and William T. Goodnow. Filed 1896-11-27 as application serial number 613,634. Assigned to the Eaton-Engle [n.b. not Eaton-Glover] Engraving Machine Company, of New York, NY.

This patent is the link which connects William S. Eaton (of Sag Harbor, NY) to Stephen D. Engle (in northeastern Pennsylvania). It specifical says that it a set of improvements [albeit minor ones] to Stephen D. Engle's machine as desribed in Engle's patents 246,737 and 275,618. Goodnow's residence is given as Sayre, Pennsylvania (in Bradford County, which is two counties over from Luzerne County). As we saw earlier, Goodnow's mother-in-law was an Engle.

Jewelers' Circular (Jun. 16, 1897)

The Jewelers' Circular and Horological Review Vol. 34, No. 20 (June 16, 1897): 36.

"The 1897 Model Eaton-Engle Engraving Machine is as necessary in your store as your lathe." 111 Nassau St., NY.

Jewelers' Circular (Jul. 7, 1897)

The Jewelers' Circular and Horological Review Vol. 34, No. 23 (July 7, 1897): 29.

Jewelers' Circular (Jul. 14, 1897)

The Jewelers' Circular and Horological Review Vol. 34, No. 24 (July 14, 1897): 17.

Jewelers' Circular (Aug. 3, 1898)

The Jewelers' Circular and Horological Review Vol. 37, No. 1 (August 3, 1898): 44.

This is an un-illustrated trade note which contains the information that Eaton & Glover are located at 111 Nassau St., New York, and that they make the Eaton-Engle.

The icon here links to a PDF of the relevant page, extracted from the Google Books digitization.

Jeweler's Circular (Sept. 7, 1898)

The Jewelers' Circular and Horological Review Vol. 37, No. 6 (September 7, 1898): 38. An ad showing an example of engraving work on the Eaton-Engle machine.

The icon here links to a PDF of the relevant page, extracted from the Google Books digitization.

Jeweler's Circular (Sept. 21, 1898)

The Jewelers' Circular and Horological Review Vol. 37, No. 8 (September 21, 1898): 19. An ad showing a cut of the Eaton-Engle machine itself. Selling the machine to people who aren't engravers.

The icon here links to a PDF of the relevant page, extracted from the Google Books digitization.

Jeweler's Circular (Sept. 28, 1898)

The Jewelers' Circular and Horological Review Vol. 37, No. 9 (September 28, 1898): 36. An ad showing a cut of the Eaton-Engle machine itself. Selling the machine to people who are engravers.

The icon here links to a PDF of the relevant page, extracted from the Google Books digitization.

Jeweler's Circular (Oct. 5, 1898)

The Jewelers' Circular and Horological Review Vol. 37, No. 10 (October 5, 1898): 37. An ad showing a cut of the Eaton-Engle machine itself. The line "Machines Cannot be Bought through Jobbers" is interesting, as it indicates a difficulty in the control of their sales channels.

The icon here links to a PDF of the relevant page, extracted from the Google Books digitization.

Jeweler's Circular (Oct. 12, 1898)

The Jewelers' Circular and Horological Review Vol. 37, No. 11 (October 12, 1898): 27. An ad showing a cut of the Eaton-Engle machine itself.

The icon here links to a PDF of the relevant page, extracted from the Google Books digitization.

This same ad appeared in next week's issue, No. 12 (Oct. 19, 1898): 45. Since the scan of it is slightly better, here it is: jewelers-circular-vol-37-no-12-1898-10-19-p045.pdf

Jeweler's Circular (Oct. 26, 1898)

The Jewelers' Circular and Horological Review Vol. 37, No. 13 (October 26, 1898): 34. An ad showing a cut of the Eaton-Engle machine itself. The copy suggests that it has always been difficult to write advertising copy which does not accidentally slight the abilities of the customer: "Any amateur can produce upon it work as good as that of the professional engraver. YOU NEED ONE!"

The icon here links to a PDF of the relevant page, extracted from the Google Books digitization.

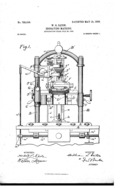

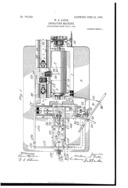

US Patent 652,892 (Eaton, 1900)

US patent 652,892, "Engraving-Machine." Issued 1900-07-03 to William S. Eaton. Filed 1900-03-01 as application serial number 6,903. Assigned to the Eaton & Glover Company, of New York, NY.

Although the patent was issued to Eaton alone, it shows the Eaton-Engle machine substantially as it appears in advertising illustrations. The primary improvement cited is the ability to vary the lateral proportion of the engraving. It is still a vertical-format drag machine. Frank B. Glover (secretary and treasurer of the Eaton-Glover Co.) signed as one of the witnesses.

Ad in Aluminum World (1902)

The Aluminum World and Brass and Bronze Industries (March 1902): 124.

In a notice in The Jewelers' Circular Vol. 39, No. 22 (Wednesday, December 27, 1899), p. 29:

"Eaton & Glover, makers of the Eaton-Engle engraving machine, 87 Nassau St. [NY], have incorporated their business under the style of the Eaton & Glover Co., with a capital of $75,000. W. S. Eaton is the president of the concern. W. T. Goodnow the vice-president, and Frank B. Glover the secretary and treasurer. In giving the reason for the incorporation the firm state that during the past three years their business has grown to such an extent that it had become too large and unweildy to be conducted by a partnership."

The timing of this announcement and the dates announced in it are interesting because they suggest that the Eaton & Glover partnership, presumably making the Eaton-Engle engraving pantograph, dates from about 1896. The patent for the machine which resembles the Eaton-Engle, however, was not even filed until March 1, 1900.

The Sag-Harbor Express for Thursday Morning, May 12, 1898, carries a "Personal Mention": "Eaton - Wiliam S. Eaton, of this place, who spends most of his time in New York, he being the senior member of the firm of Eaton & Glover, No. 111 Nassau St., is now home on a short visit." (This newspaper has been digitized by Tom Tryniski and is available on his "Old Fulton NY Post Card" website at: http://fultonhistory.com/ )

The 1901 edition of The Trow (formerly Wilson's) Copartnership and Corporation Directory of New York City, Volume 49, lists: "Eaton & Glover Co. (N.Y.) (William S. Eaton, Pres.; Frank B. Glover, Sec. Capital, $75,000. Directors: William S. Eaton, Frank B. Glover, William T. Goodnow, Henry Dryfoos Jr.) 87 Nassau & r 17 John."

US Patent 660,790 (Eaton, 1900)

US patent 660,790, "Engraving-Machine." Issued 1900-10-30 to William S. Eaton. Filed 1900-08-03 as application serial number 26,232. Not assigned. This is a non-pantographic multispindle ("gang") routing or rotary engraving machine.

US Patent 663,563 (Eaton, 1900)

US patent 663,563, "Engraving-Machine." Issued 1900-12-11 to William S. Eaton. Filed 1900-09-17 as application serial number 30,253. Assigned to the Eaton & Glover Company, of New York, N.Y.

This is a drag engraver (like the Eaton-Engle), and the improvement identified in this patent is merely one for engraving long objects (such as thermometers), but it is significant because the overall layout of the machine now resembles the Eaton & Glover "New Century" as shown in advertisements.

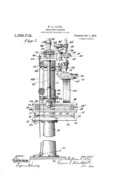

US Patent 729,758 (Goodnow & Eaton, 1901/1903)

US patent 729,758, "Engraving-Machine." Issued 1903-06-02 to William T. Goodnow [Sayre, PA] and William S. Eaton [Sag Harbor, NY]. Filed 1901-09-07 as application serial number 74,698. Assigned to The Eaton & Glover Company, of New York, N.Y., A Corporation of New York.

Note that although this patent appeared after William S. Eaton's patents 696,950, 696,951, and 728,556, it was filed in September 1901. If I were to hazard a guess ( and it is only a guess!), my suspicion is that the split between William S. Eaton and the Eaton & Engle Company came between Sept. 7, 1901 (when this present patent was filed) and November 1, 1901 (when Eaton renewed his earlier applications for what became 696,950 and 696,951.

This patent specifically cites Eaton's patent 652,892 (which is basically the Eaton-Engle machine as marketed) but has an overall arrangement resembling the Eaton & Glover "New Century." It is a vertical format pantograph drag engraving machine which looks identical to the machines shown in 1907 Eaton & Glover (Sayre, PA) advertisements (see below) .

A frustratingly brief Google Snippet of the public domain journal Current Advertising, Vol. 10 (1901) says:

"'Engraving that Pays' is the title of an excellent booklet-catalogue issued by the Eaton & Glover Company, 87 Nassau Street, New York. The book is an advertisement for the 'New Century' Engraving Machine, an applicance by which the makers claim it is possible to do jewelry engraving more quickly and profitably than by slow, tedious and expensive hand methods."

Catalog No. 61 ("Trade Catalogues from the 19th and 20th Centuries") of High Ridge Books, Inc. (an antiquarian bookseller) lists a copy of this item for sale. This catalog entry dates it firmly to 1901 and notes that it is a 32 page octavo booklet with one color plate showing two models of machine.

New Century Fragment (ca. 1901)

In an antique store some years ago (long before I became involved with pantographs or metal type) I picked up an eight-page fragment of a brochure for the Eaton & Glover New Century machine. It is possible that this is a part of "Engraving that Pays," but I don't know for certain if it is or not. It is interesting in that it contains an engraving of the machine (shown in operation by a woman in a jewelry store setting, in public/display space).

(The image above links to a 1024 pixel wide JPEG version of this cut. Here is the full-resolution (1200dpi RGB) scan (22 Megabytes, 3000x4000 pixels): eaton-glover-new-century-engraving-machine-brochure-1200rgb-03-crop-pantograph-3000x4000.png)

Ashburton [NZ] Guardian (1903)

Page 2 of The Ashburton Guardian. Vol. 21, Issue 5090 (1903-04-29). This is a New Zealand newspaper with an article reporting the importation from the US of a "New Century" engraving machine.

The icon at left links to a PDF of this page made from the high-resolution PNG scan of this image made by the National Library of New Zealand. It is available online in their PapersPast archive at http://paperspast.natlib.govt.nz/cgi-bin/paperspast?a=d&d=AG19030429.1.2&e=-------10--1----0-- (They also supply a PDF version, but it has some PDF technical issues, so instead I made a PDF of their PNG version. Here is the original PNG version: ashburton-guardian-volume-21-issue-5090-1903-04-29-p0002-includes-eaton-engle-new-century-engraving-machine-AG19030429-1.png)

Ashburton [NZ] Guardian (1903)

After purchasing his New Century machine, J. V. DeBeer advertised its use. These are two pages from the The Ashburton Guardian. Vol. 21, Issues 5959 (1903-05-09) and 5973 (1903-05-28). The have been digitized by, and are available through, the National Library of New Zealand in their PapersPast archive.

The "New Century" would seem to have been used in conjunction with some of Eaton's earlier methods of producing composite patterns and using shading devices. In a posting to the Engravers' Cafe website on 2009-11-28, Francis Kisner, in commenting on some modern monograms, said:

"... the New Century Engraving Machine around 1900. The designs were printed on a kind of oilskin paper so they could be layered on top of each other and the overall design traced to produce the outline. The machine had a clear plastic circle with parallel grooves cut into one side. By laying the plastic over the design, it was possible to produce shading."

http://www.engraverscafe.com/archive/index.php/t-6249.html?s=209639e7bdb21560fa5e57999f1e88d0

US Patent 696,950 (Eaton, 1902)

US patent 696,950, "Routing or Engraving Machine." Issued 1902-04-08 to William S. Eaton. Filed 1899-11-23, renewed 1901-11-01 as application serial number 80,809. Not assigned.

This is a vertical format rotary engraving pantograph. It is notable in this history for two reasons, one business and one technical. On the business side, it is interesting that this patent for a machine developed by at least 1899 (that is, before the "New Century" machine) was not assigned to Eaton & Glover. On the technical side, this machine is interesting because it is the first Eaton pantograph to employ a ball-bearing table. In this case it is through the use of an X-Y table (in the later "Engravers' and Printers' Machinery Co." machines it was through the use of three large balls). Yet in several respects (such as its "offset" tracer) this machine still resembles the Engle machines. I do not know whether or not it was ever produced, but it seems to be an interesting transitional design.

US Patent 696,951 (Eaton, 1902)

US patent 696,951, "Routing or Engraving Machine." Issued 1902-04-08 to William S. Eaton. Filed 1899-11-27, renewed 1901-11-29 as application serial number 84,096. Not assigned.

This is a curious machine primarily designed to keep the tracer vertical through a system of linkages. While it employs the ball-bearing table of patent 696,950, and though their patents were filed and issued simultaneously, it does not otherwise seem related. I'm not quite sure what to make of it.

US 728,556 (Eaton, 1903)

US patent 728,556, "Engraving-Machine." Issued 1903-05-19 to William S. Eaton. Filed 1902-07-29 as application serial number 117,448. Assigned to Engraving Company of America, of New York, N.Y.

On the business side, this patent is interesting because it was issued to Eaton (in Sag Harbor) but assigned to "Engraving Company of America" in NY (not to Eaton & Glover). Since Eaton & Glover seem to have continued making the "New Century" machine after a move to Pennsylvania somewhere around this time, this patent assignment suggests a split between William S. Eaton and the Eaton & Glover company.

On the technical side, this is a vertical pantograph rotary engraver. It employs a variation of Eaton's earlier ball-bearing table (using wheels in this case) and iit attempts to keep the tracer upright through a series of linkages (as Eaton did in patent 696,951). Yet it has the same overall arrangement of its frame as the "New Century."

US Patent 792,252 (Eaton, 1905)

US patent 792,252, "Engraving Machine." Issued 1905-06-13 to William S. Eaton. Filed 1904-07-05 as application serial number 215,341. Not assigned.

This is for an electromagnetically controlled engraving machine. While it is interesting in its own right, it seems unrelated to the other machines discussed here.

US Patent 816,307 (Eaton, 1906)

US patent 816,307, "Engraving-Machine." Issued 1906-03-27 to William S. Eaton. Filed 1905-08-23 as application serial number 276,348. Not assigned.

An interesting little addition to the cutting spindle to allow repeatable cutter depth positioning through an electrical signal.

A Google snippet from the public domain Journal of the Proceedings of the Tioga County [NY] Board of Supervisors (1905) lists, under "Names of Incorporated Companies Liable to Taxation" "The Eaton & Glover Company ... 300.00 [Assessme't] ... 1.35 [tax]" and on page 98 very similar information with the same assessment but a tax of 1.80. Tioga County is on the border with Pennsylvania.

An advertisement cut from a now-destroyed copy of an unidentified 1907 magazine (I did not buy it; this is a deplorable practice) says the following about the Eaton & Glover "New Century" (if the inch-sign and center-dot show up strangely, make sure your page encoding is set to UTF-8):

"NEW CENTURY Engraving Machine

"By redesigning several parts of our machine we have secured a rigidity which greatly facilitates the engraving of the harder metals, such as BRASS, NICKEL WATCH CASES; PLATED WARE, Etc.

"This feature, however, reduced somewhat the range of the machine as regards size of letter that can be engraved from the same pattern letter.

"For example, our present machine as constructed, will engrave one-half the size of pattern letter to zero. With the machine equipped with the new style parts, the engraving can be made from 1″ to 3·32″ if pattern is 2″, as is the case with our No. 1 script capitals, and 11·32″ to 1·32″ for small letters from No. 1 script. The patterns for small script are about 22·32″.

"When you use a NEW CENTURY Engraving Machine, you do your engraving without trouble.

"Your hand don't [sic] "get out," you don't make slips, and you can do about four times as much engraving in a given time than you could by hand.

"A letter we have just received from a customer says:

"I am well pleased with the machine, and am sure it will do all you claim for it. I am a good hand engraver, having been at the bench nearly twenty years, but I find the NEW CENTJRY so much help that I would not care to part with it.

In the 1908 edition of The Trow (formerly Wilson's) Copartnership and Corporation Directory of New York City (NY: Trow, 1908), there is a listing for: "Interboro Engraving Co. (N.Y.) (William S. Eaton, Pres.; Frank B. Glover, Sec.; E. Percy Eaton, Treas. Capital, $3,000. Directors: William S. & E. Percy Eaton, Frank B. Glover, Charles A. Reinholdt) 108 Fulton R. 1306."

The 1912 edition of Walden's stationer and printer Vol. 35, part 2 carries this note: "The Interboro Engraving Company, 108 Fulton Street, reports in addition to many new customers, a considerable increase in sales for 1912. With their unusual equipment and facilities enabling them to furnish their customers with practically a twenty-four-hour service in the engraving of steel dies and copper plates, they have nothing but enthusiasm for the outlook for the new year." (p. 12)

108 Fulton is the same address occupied by "Engravers' and Printers' Machinery Co. in 1911, and E. P. Eaton was a director of both companies, so it is reasonable to conclude a close relationship between the two businesses.

Interestingly, no Engle or Goodnow appears in association with either company. It would seem that the Eaton & Glover company went to Pennsylvania (where Engles and Goodnows lived), but that the Eatons and Glover (the individuals) remained in New York. After having lent his name to the Eaton & Glover company, Eaton's subsequent business ventures had uncompromisingly generic names.

A notice in the journal Mill Supplies Vol. 1, No. 3 (March, 1911) says:

"The Engravers' and Printers' Machinery Co., New York, has been organized by J. F. Fowler, E. P. Eaton and W. Schwartz with a capital of $100,000 to manufacture engraving and printing machinery." (p. 129)

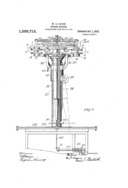

US Patent 1,039,712 (Eaton, 1912)

US patent 1,039,712, "Engraving-Machine." Issued 1912-10-01 to William S. Eaton. Filed 1910-09-10 as application serial number 582,629. Not assigned.

Although it was not assigned, with this and Eaton's two other 1912 pantograph patents we can see the machines manufactured by the Engravers' and Printers' Machinery Co. This is a vertical-format rotary pantograph engraving machine which employs an X-Y table on bearings (much like Eaton's machine of patent 728,556 (1903) that had been assigned to Engraving Company of America. But it is arranged around a single vertical column, unlike all earlier Engle/Goodnow/Eaton machines.

However, unlike the machines shown below in The Inland Printer (1911), Salade (1917), and The American Machinist (1919), it employed a curious and somewhat awkward arrangement where the pattern was above the engraving cutterhead and much of the apparent frame actually pivoted.

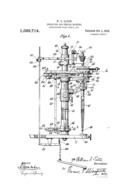

US Patent 1,039,713 (Eaton, 1912)

US patent 1,039,713, "Etching Machine." Issued 1912-10-01 to William W. Eaton. Filed 1910-10-29 as application serial number 589,667. Not assigned.

This is the machine shown in The Inland Printer (1911) and Salade (1917). It is the drag-engraving counterpart to the rotary-engraving "Model D" shown in The American Machinist (1919). The two primary differences between these two machines and earlier Eaton machines are (a) that the pantograph is purely vertically arranged, and (b) that the working table moves on three large balls rather than the smaller (more conventional) ball bearings or wheels of his earlier designs. This machine is also arranged around a single vertical column, unlike Eaton's pre-1912 designs.

It is interesting that this machine is described as an "etching" machine. It is itself a drag engraving machine. But Eaton describes its use thus: "My invention relates to a machine adatpted to mechanically remove the surface coating upon a plate to be etched, the actual removal of the metallic face of said plate being accomplished in the usual and well-known manner." Salade ( Plate Printing... (1917); see below) says: "After the engraving machine has outlined with a diamond point the pattern on the steel or copper plate, the plate is engraved by hand, or is treated and given the acid 'bite' the same as though a vermilion ground had been applied." (p. 16).

US Patent 1,039,714 (Eaton, 1912)

See the entry for this patent in the Engravers' and Printers' Machinery Co. Model D, below.

The machine shown in the three advertisements from Volume 48 The Inland Printer (1911), below, is the same machine described in patent 1,039,713, above, and in Salade (1917) and Hackleman (1922), below. It is a vertical-format drag machine employed to prepare plates for etching. The company name is "Engravers' and Printers' Machinery Co., Inc." and the address is "108 Fulton Street, New York City, NY."

Inland Printer (Oct. 1911)

The Inland Printer Vol. 48, No. 1 (October 1911): 48.

Inland Printer (Nov. 1911)

The Inland Printer Vol. 48, No. 2 (November 1911): 188.

Inland Printer (Dec. 1911)

The Inland Printer Vol. 48, No. 3 (December 1911): 365.

The three images above from Vol. 48 of The Inland Printer were digitized by Google from the University of Michigan copy and are available via The Hathi Trust (Hathi ID: mdp.39015086783720). The icons here link to local copies of these pages at full available resolution.

The following announcement appeared in The Printing Trade News, Vol. 42, No. 26 (June 25, 1912): 46:

'ADVERTISING ITS NEW MODEL "C."

'The Engravers' and Printers' Machinery Co., 108 Fulton street, New York, recently sent out advertising matter describing its Model C engraving machine. The concern submitted a little sheet of a variety of styles of engraved lettering, all produced on the machine, some with a little additional hand work, some with none at all. The impression was form a plate not carefully doctored by a great deal of hand touching-up but produced simply in the ordinary run of work and in the average amount of time by a ten-dollar-a-week boy, the only hand finishing being where the character of the letter makes its completion by hand more rapidly than if completed entirely by the machine. The results were excellent."

Salade (1922)

Salade, Robert F. Sales Suggestions for Paper Box Manufacturers. (Lafayette, Indiana: Shears Publishing Company, 1922): extract of pp. 126-167. This references, but does not illustrate, the Model C Engraving Machine made by the Engravers' and Printers' Machinery Co., of Sag Harbor, NY.

Salade. Plate Printing.... (1917)

Salade, Robert F. Plate Printing and Die Stamping. (NY: Oswald Publishing Company, 1917). This illustrates a drag pantograph engraving machine and discusses its use for producing printing plates. The machine is not named, but is clearly one made by the Engravers' and Printers' Machinery Company.

This book has been digitized by the Library of Congress and is available in full on The Internet Archive at: http://www.archive.org/details/plateprintingdie00sala/. The icon here links to an extract of the three pages devoted to engraving machines.

Here's the cut of the engraving machine, from p. 31 of Salade:

Here is the same cut, as it appears in Charles W. Hackleman's Commercial Engraving and Printing. Second Edition. (Indianapolis, IA: Commercial Engraving Publishing Company, 1924): p. 529 (figure 1230). The original was quite finely printed (it was a book on commercial engraving, after all); if you click through on the image below you'll get the full-resolution 1200 dpi RGB scan (20 Megabytes). The machine is not identified by name in the text.

US Patent 1,039,714 (Eaton, 1912)

US patent 1,039,714, "Engraving and Similar Machine." Issued 1912-10-01 to William S. Eaton. Filed 1911-06-02 as application serial number 630,853. Not assigned.

This is the rotary-engraving counterpart to the drag-engraving (etching) machine described in Eaton's patent 1,039,713 (1912). It is a vertical-format rotary pantograph engraving machine with a straight-line pantographic mechanism and a worktable moving on three large balls. It is arranged around a single column.

With this machine we come to a pantograph substantially the same as the ones as used by Frederic W. Goudy to engrave the matrices for many of his printing types. As such, it is one of the more important pantographs ever, yet it is almost completely forgotten today. This machine has one of the greatest ratios of importance to obscurity one is ever likely to encounter.

American Machinist (1919; Model D)

American Machinist. Vol. 51, No. 1 (July 3, 1919): 41. ("Shop Equipment News" column) This shows the Model D pantograph engraving machine, "the product of the Engravers and Printers Machinery Co., Sag Harbor, N.Y." This is a rotary pantograph engraving machine with the capability of expanding or condensing the design proportions. This is very similar to the machines that Goudy used (his lacked the "ladder-like" stabilizing structure shown behind the column on this machine).

This volume has been digitized by Google from the Princeton University copy and is available via The Hathi Trust (Hathi ID: njp.32101048995185). The icon at left links to a local copy of the relevant page image from the Hathi Trust presention.

The American type maker Frederic W. Goudy (the third most prolific, but certainly the best known, letterform designer for type of the 20th century) was uncommon in that he not only drew type designs but in many cases actually performed all of the steps of type-making himself. A few other letterform designers of his era learned the older techniques of punchcutting, but only Goudy had the gumption to learn industrial methods of matrix making and typefounding. He is therefore of great importance not merely in the history of design but also in the practical continuation of metal type-making today.

Given Goudy's high profile and his unusual involvement in matrix engraving, the identities of the engraving machines that he used would seem to be of great interest. Yet to the best of my knowledge their identities have never been determined (or at least never published). Their identities have also been obscured at times by statements that they were Benton engraving machines. (As will be seen, they were not. Such a statement lacks historical clarity, in any case, because at this time Benton machines were not available outside of ATF. Not every vertical-format pantograph engraver is a Benton, and a Benton machine, while a marvel of engineering, is not a prerequisite for making type.) Goudy himself was coy about the identities of his machines, never mentioning a manufacturer by name. He said only that he employed a machine which had been made for other kinds of work but which had been adapted by the manufacturer, at his request, to meet his matrix engraving needs.

Goudy employed at least three matrix engraving machines at different times. Two of these were used before 1939, when a fire destroyed his workshop. The third was a replacement machine acquired after the fire. From a study of the existing published photographs of these machines, it would appear that they were all substantially the same model.

More particularly, they all look very much like the Engravers' and Printers' Machinery Company Model D. (The only major difference between them and the Model D which is discernable in the published photographs is that Goudy's machines lack the "ladder-like" stabilizing structure behind the column.) Significantly, they all have the "three ball" arrangement unique to the machines covered by Eaton's patents 1,039,713 and 1,039,714. Since this "three ball" arrangement was patented and was unique to the Eaton machines, Goudy's machines must perforce have been made by his company. If Goudy's machines weren't exactly the Model D, then they were its close cousins.

Unfortunately, while there are several published photographs which show Goudy's matrix engraving machines relatively clearly, none of these are in the public domain.

Perhaps the best published photograph is the one which appears on p. 109 of Goudy's book Typologia (Berkeley, CA: The University of California Press, 1940) (Reprinted in paperback in 1977. This book is also online on Google Books by arrangement with the US Press. Find it using the Google Books Advanced Search at http://books.google.com/advanced_book_search/ ) This shows Goudy at one of his pre-1939 machines.

A pre-1939 matrix engraver is also shown in the background of a photograph of Goudy's working pattern pantograph (a Deckel) on pp. 90-91 of Bruckner, D.J.R. Frederic Goudy (NY: Harry N. Abrams, 1990). This photograph is from the Melbert B. Cary Graphic Arts Collection at Rochester Institute of Technology.

His post-1939 matrix engraver is shown on p. 117 of Andrew R. Boone's article "Type By Goudy" in Popular Science Vol. 140, No. 4 (April 1942): 114-119. (This is online both by arrangement with the publisher via Google Books and at the Modern Mechanix blog at http://blog.modernmechanix.com/

The post-1939 machine is also shown in Bruckner (pp. 28-29).

I know of only three published photographs which are out of copyright and which show his matrix engraver.

(There may be others in Advertising and Selling, Vol. 11 (1928) or Printing, Vol. 69 (1945), but I have not yet located copies of these journals to verify the existence or status of these possible images.)

The photograph below is from a two-page photo spread entitled "Type: Frederic W. Goudy Here Demonstrates the Design of One of Advertising's Oldest Devices, a Type Face" in the advertising trade journal Advertising and Selling. Vol. 32, No. 6 (May, 1939): 38-39. It shows Goudy just before the 1939 fire which destroyed his studio, working at his Engravers' and Printers' Machinery Co. matrix engraving machine. (Portions of his Deckel pantograph, used for engraving working patterns, are shown in the background and slightly confuse the image.)

The image above is a link to a 2048 pixel wide version which is actually presented in the General Literature on Making Printing Matrices and Types Notebook. See that Notebook for the entire photographic layout both as a PDF and as high-resolution scans.

The photograph below was published by Goudy himself in his irregular journal Ars Typographica, Vol. 1, No. 4 (Autumn, 1934). It shows him at a matrix engraving pantograph in his studio in the old mill at the home he called "Deepdene" in Marlboro, NY. Regrettably, the style of the photograph is one where Goudy is in focus but his machine is not. Still, having seen a pantograph engraving machine such as the Engravers' and Printers' Machinery Co. Model D, it is clear that this is a very similar machine.

(The image above links to a 2048 pixel wide version of this photograph, which quite frankly shows you everything you're ever going to see in it. But since it is a photograph of some historic importance, here is the full resoution 1200dpi RGB PNG version of this scan of it (88 Megabytes): ars-typographica-vol-1-no-4-1934-1200rgb-goudy-at-matrix-pantograph.png )

(This number of Ars Typographica is online at The Internet Archive, in a crude but useful scan that I did from my copy, at ../../ Typefoundry and Press -> Making Printing Matrices and Types -> Literature -> General -> Lewis, and also in The Internet Archive at http://www.archive.org/details/GoudyArsTypographicaVol1No4 )

The photograph below shows Goudy at work on his Deckel pantograph engraving a working pattern. But if you enlarge it (click on it, or download it and view it using a proper image viewer), you can just see a view of the back of one of his matrix engraving machines on the right. It is from Bernard Lewis' book Behind the Type: The Life Story of Frederic W. Goudy (Pittsburgh, PA: Department of Printing, Carnegie Institute of Technology, 1941).

(Lewis' book is online at ../../ Typefoundry and Press -> Making Printing Matrices and Types -> Literature -> General -> Lewis, and also in The Internet Archive at http://www.archive.org/details/LewisBehindTheType1941 )

US Patent 1,147,152 (Eaton, 1915)

US patent 1,147,152, "Printing-Machine." Issued 1915-07-20 to William S. Eaton. Filed 1912-10-12 as appliation serial number 725,379. Assigned to American Bank Note Company, of New York, N.Y. This is a rotary intaglio (rotogravure) printing press.

US Patent 1,166,513 (Eaton, 1916)

US patent 1,166,513, "Geometrical Machine." Issued 1916-01-04 to William S. Eaton. Filed 1913-02-20 as application serial number 749,616. Assigned to American Bank Note Company, of New York, N.Y.

This and several subsequent patents for "geometrical" machines are built around pantographic engravers of the type described in 1,039,713 and 1,039,714, but what they really are are methods of turning a pantograph into a geometrical engine. They are closely allied with ../../../ Machine Shop -> Rose Engine Work.

US Patent 1,235,668 (Eaton, 1917)

US patent 1,235,668, "Pantographic Engraving-Machine." Issued 1917-08-17 to William S. Eaton. Filed 1914-06-09 as application serial number 343,956. Not assigned. This is a horizontal-format pantograph which does not seem to be directly associated with any of Eaton's earlier machines.

US Patent 1,241,721 (Eaton, 1917)

US patent 1,241,721, "Geometrical Machine." Issued 1917-10-02 to William S. Eaton. Filed 1913-10-23 as application serial number 796,816. Assigned to American Bank Note Company, of New York, N.Y.

US Patent 1,241,722 (Eaton, 1917)

US patent 1,241,722, "Geometrical Machine." Issued 1917-10-02 to William S. Eaton. Filed 1913-10-23 as application serial number 796,817. Assigned to American Bank Note Company, of New York, N.Y.

US Patent 1,241,723 (Eaton, 1917)

US patent 1,241,723, "Geometrical Machine." Issued 1917-10-02 to William S. Eaton. Filed 1913-10-23 as application serial number 796,818. Assigned to American Bank Note Company, of New York, N.Y.

US Patent 1,275,408 (Eaton, 1918)

US patent 1,275,408, "Art or Method of Etching Steel or Other Like Plates." Issued 1918-08-13 to William S. Eaton. Filed 1916-11-28 as application serial number 133,874. No drawing. Not assigned.

This is a process intended for the production of master patterns for pantographic engraving. If I understand Eaton correctly (and I'm no electrochemist!) he is claiming a process which uses not a strongly corrosive but rather a generally noncorrosive etching bath which, by electrolytic action, he causes to decompose into a strong base (cholorine; he says "chlorin," but that cannot be correct; he also says "acid," but chlorine is a base) at the surface to be etched. The advantage he claims is that this method reduces the undercutting inevitable with purely chemical etching.

US Patent 1,294,639 (Eaton, 1919)

US patent 1,294,639, "Geometrical Machine." Issued 1919-02-18 to William S. Eaton. Filed 1917-03-26 as application serial number 157,430. Assigned to American Bank Note Company, of New York.

This would seem to be an automated Straight-Line Engine for geometric engraving. (It is not based on a pantograph, unlike Eaton's earlier "geometric machines" assigned to American Bank Note Company.)

US Patent 1,372,494 (Eaton, 1921)

US patent 1,372,494, "Priming-Cup." Issued 1921-04-22 to William S. Eaton. Filed 1917-02-15 as application serial number 148,709. This is a device for assisting in the starting of a 4-cycle gasoline engine. It seems quite unrelated to all of Eaton's other patents; one wonders how things were going in the engine room of the Zar.

US Patent 1,421,426 (Eaton, 1922)

US patent 1,421,426, "Etching or Like Machine." Issued 1922-07-04 to William S. Eaton. Filed 1921-12-31 as application serial number 522,019. Not assigned. Using a pantograph as a ruling machine.

US Patent 1,551,648 (Eaton, 1925)

US patent 1,551,648, "Engraving Machine." Issued 1925-09-01 to William S. Eaton. Filed 1922-12-04 as application serial number 604,650.

In form this is a curious return to the "New Century." It is a rotary pantograph engraver adapted for marking the panel dials of radios. It is interesting also that it specifies a flexible shaft drive for the rotary engraver.

US Patent 1,603,332 (Eaton, 1928)

US patent 1,603,332, "Etching or Like Machine." Issued 1926-10-19 to William S. Eaton. Filed 1923-11-19 as application serial number 675,642. Not assigned.

Basically the Engravers' and Printers' Machinery Co. machine of Eaton patent patent 1,039,713 adapted for a quite unusual form of use with the pattern on an "easel."

US Patent 1,621,317 (Eaton, 1927)

US patent 1,621,317, "Engraving or Like Machine." Issued 1927-03-15 to William S. Eaton. Filed 1923-08-12 as application serial number 650,994.

An adaptation of the Engravers' and Printers' Machinery Co. style of "large ball" working table machines to multiple spindles.

US Patent 1,680,097 (Eaton, 1928)

US patent 1,680,097, "Printing Plate." Issued 1928-08-07 to William S. Eaton. Filed 1926-08-31 as application serial number 132,666. An intaglio printing plate consisting of a thin plate of hardened steel soldered to a thicker plate of cheap, soft steel.

US Patent 1,858,465 (Eaton, 1932)

US patent 1,848,465, "Engraving Machine." Issued 1932-03-08 to WIlliam S. Eaton. Filed 1926-04-15 as application serial no. 102,157. A multiple-spindle engraving machine using an electrically encoded pattern.

US Patent 1,857,570 (Sackers et. al., 1932)

US patent 1,857,570, "Engraving Machine." Issued 1932-05-10 to Peter Sackers, Irwin Reinhart, and Theodore G. Straub. Filed 1928-12-31 as application serial number 329,613.

This is not an Eaton patent per se (the three inventors are all of Evansville, Indiana and presumably unrelated to Eaton). It is an attachment for pantograph engraving machines which would naturally use reverse-reading patterns to allow the use of right-reading patterns. It cites specifically the machines of patent 1,039,713 (the Engravers' and Printers' Machinery Company drag machine) and patent 1,603,332 (Eaton's "easel" variation of it).

The Sag Harbor Express for Thursday Morning, April 1, 1920 carried the following news item:

"William S. Eaton, president of The Engravers and Printers' Machinery Company of this place, who has recently erected a large factory on Jermain avenue, has resigned his position, and his son, E. Percy Eaton has been elected president in his place. The elder Mr. Eaton has been a prominent figure in this place for many years, coming here, if we mistake not, as forman of the engraving room of the Fahys Watchcase Factory. Possessing an inventive mind he had once article after another patented, but none, with think, met with that success as did the engraving machine, for the manufacture of which he erected the factory above alluded to, his first structure for the work proving too small for the increasing business. And now, after some fourty [sic] years of industry, he surrenders the business to his son, who is abundantly able to successfully carry it on, that the paternal head may bass some of his future years in less arduous work."

Eaton wasted no time in undertaking this less arduous work, for on the same page appears a note that "Commodore William S. Eaton of the Sag-Harbor Yacht Club, [recently?] returned from Florida, has sold his fourty [sic, and Lloyds says it was 50] foot power yacht Zar, now on its way from Florida. The Commodore has purchased a new sixty foot power yacht, from which he will fly his flag."

(This newspaper has been digitized by Tom Tryniski and is available on his "Old Fulton NY Post Card" website at: http://fultonhistory.com/ )

However, The Sag Harbor Express for Thursday Morning, May 13, 1920 (the same number which gave the expected commissioning date of his 65 foot yacht Helen M., see below, also notes that "To manufacture watch cases and watch case parts, C. W. Butts has incorporated his newly organized company. Directors for the first year are Mr. Butts, W. S. Eaton and W. E. Ferguson. The concern is making watch case parts at the old factory building of the Engravers & Printers' Machine [sic] Co., on Palmer Terrace."

(This newspaper has been digitized by Tom Tryniski and is available on his "Old Fulton NY Post Card" website at: http://fultonhistory.com/ )

While the various Eaton engraving machines are now nearly forgotten it is clear that William S. Eaton's business undertakings were very successful. The Brooklyn Blue Book and Long Island Society Register for 1920, for example, lists William S. Eaton as the Commodore of the Sag Harbor Yacht Club (and his son E. P. Eaton as the Secretary).

Lloyd's Register of American Yachts for 1917 gives this same information for the Yacht Club, and notes further that he was owner of the Yacht "Zar" (formerly the Cilla, Sim Too, and Vincent III), a 50 foot wooden motor yacht built by Britt Bros. in West Lynn, MA in 1910.

As noted earlier, a 50 foot yacht was insufficient for a man of his standing in society. The journal Boats, Volume 17, carries two notices (both on p. 40). First: "50-ft. bridge deck cruiser Zar, sold for W. S. Eaton, Sag Harbor Y. C., to Jesse B. Riggs for use on Chesapeake Bay." Second: "65-ft. motor cruiser Helen M., sold for Joseph Mercadante, N. Y. Athletic Club, to Commodore W. S. Eaton, Sag Harbor Y. C. for Long Island Sound Service."

The Sag Harbor Express for Thursday Morning, May 13, 1920 notes that "Commodore W. S. Eaton's new power yacht, the Helen M., is expected to be in commission early in June, with Capt. David Bennett, as master."

(This newspaper has been digitized by Tom Tryniski and is available on his "Old Fulton NY Post Card" website at: http://fultonhistory.com/ )

In his later years William S. Eaton also took up the painting of landscapes. Several of these may be found relatively easily by searching historic listings of various art auction houses online.

In 1943, Steel [journal] vol. 112, Modern Industry, vol. 5 The Tool Engineer, Vol. 12 list Eaton Engravers Machinery Corp., Sag harbor.

In 1967, Macrae's Blue Book, Vol. 1 lists Eaton Engravers Machinery Corp., Sag Harbor.

The history of Eaton's engraving machines continues with the Cronite Company, which remains in business today. Detailed historical information on the Cronite pantographs is difficult to find, however. I am summarizing here from various published sources, and trying very hard to get the details right. I would be happy to correct any mistakes which might be present.

Their official corporate history is online on their website at: http://cronite.com/company.htm According to this history, they date back to the founding of a jewelry engraving firm in New York City by Ernest J. Meuench in 1886. This business continued with Frank N. Steffens, from 1904. From the late 1920s, under the trade name "Cronite," they branched out into the chrome facing of steel dies.

Their corporate history notes that in 1934 "they purchased the steel polishing equipment from Engravers & Printers Machinery Co. in Sag Harbory, NY."

It isn't clear at what point they acquired the line of pantograph engravers from E&PM Co. (as I presume they did), but they note that in 1974 they purchased "the Library of Engravers Styles" of "Eaton Sag Harbor, L.I., New York." This probably marks the end of Eaton's firm as such.

At the time of writing (2013), they list their Zero Engraving Machine, a descendent of the Eaton / E&PM Co. Model C, as available for sale. This is a remarkable continuity of technical history over more than 110 years.

Steffens. Engraved Stationery Handbook. (1950, 1969)

Steffens, Robert N. Engraved Stationery Handbook. The first edition was (New York City: The Cronite Co., Inc., 1950). The second, revised, edition was (North Bergen, NJ: The Cronite Co., Inc., 1969).

This is a detailed technical account of the procedures for engraving and printing from steel dies. It covers hand, photographic, and pantographic methods (as well the Cronite Ruling Machine). It provides detailed instructions for the use of the Cronite pantograph engraving machines, and has good photographs of at least two different models. It does not, however, cover the history of their pantographs.

The Cronite pantographs as manufactured vary in detail, but they all descend from the machine Eaton patented in 1902. The only Cronite machines I have seen illustrated are drag engraving machines; I do not know if Cronite manufactured any rotary engraving versions. From the Engraved Stationery Handbook, it can be inferred that Cronite manufactured three models. In historical order, I think that these were:

I presume that the Model C, which Steffens refers to as an older machine, is essentially the Engravers' and Printers' Machinery Co. Model C. Stffens illustrates in several locations (e.g., pp. 84 and 89 of the 1969 edition) pantograph engravers which have the same ball mechanism for the upper table as the E&PM Co. Model C (but he does not specifically call out the machine's name).

We know both from Steffens book and the current Cronite website tha the Zero Engraving Machine is the most recent development of this pantograph. We may presume that the Model C was essentially the same as the E&PM Co. Model C. This implies that the "Universal Engraving Machine" must have come between the two.

US Patent 2,668,355 (Clark, 1954)

US patent 2,668,355, "Engraving Device." Issued 1954-02-09 to John Clark. Filed 1953-06-29 as application serial number 364,860.

This is a patent for a duplicate engraving attachment. I am unaware of any link between Clark and the Cronite company, and do not wish by showing this patent here to suggest any. But Clark chose to show his invention as fitted to a pantograph which he explicitly cites as "The Universal Engraving Machine ... manufactured by the Cronite Co., Inc. of North Bergen, New Jersey." This gives June of 1953 as a date by which Cronite had begun the sale of the Universal Engraving Machine.

The illustration in this patent is also interesting because it shows a machine which uses balls between flat disks (like the E&PM Co. Model C) rather than retained in "V" tracks (like the later Zero Engraving Machine). However, on p. 83 of the 1969 edition of Stationery Engraving Handbook, Steffens implies that cast-iron '"V" track carriages' were used prior to the Zero Engraving Machine (and thus by implication on the Universal). I do not fully understand the history of the machines here.

Steffens (on p. 82 of the 1969 edition) describes the Zero Engraving Machine as "new" and as capable of reductions down to an "infinitely small" size (hence the name, "Zero"). The machine uses '"V" track carriages" (in Steffens' terms, p. 83) rather than flat plates, to constrain its large ball bearings. He further notes that with the Zero these are aluminum with cast-in stainless steel segments, rather than the cast iron of earlier machines. An illustration of this machine may be seen on the Cronite website: http://cronite.com/index.php/pantograph

In Engraved Stationery Handbook (1969 edition), Steffens refers to several improvements by Cronite in these machines. These include:

I do not yet have any photographs of Cronite pantographs, of any model, that I have permission to show here. A search online for Cronite pantographs, however, will turn up several machines in various "home machinist" and engraving forums and websites.

US patent specifications are in the public domain by law.

The issues of the Ashburton Guardian from 1903 are in the public domain due to the expiration of all possible copyright. The images from them here remain in the public domain.

The 1898 volume of The Jewelers' Circular is in the public domain due to the expiration of all possible copyright. The images from it here remain in the public domain.

The 1902 volume of The Aluminum World is in the public domain due to the expiration of all possible copyright. The images from it here remain in the public domain.

Hackleman's Commercial Engraving and Printing is in the public domain due to failure to renew copyright as was then required. The images from it here remain in the public domain.

The 1939 volume of Advertising and Selling is in the public domain due to failure to renew copyright as was then required. The images from it here remain in the public domain.

Ars Typographica Vol. 1, No. 4 was published in the US without copyright notice at a time when such notice was required to secure copyright. It therefore passed into the public domain upon initial publication. This digital reprint remains in the public domain.

All portions of this document not noted otherwise are Copyright © 2012-2013, 2022 by David M. MacMillan.

Circuitous Root is a Registered Trademark of David M. MacMillan.

This work is licensed under the Creative Commons "Attribution - ShareAlike" license, version 4.0 International. See http://creativecommons.org/licenses/by-sa/4.0/ for its terms.

Presented originally by Circuitous Root®