"Spotting" is an abrasive finishing procedure in which a regular pattern of (usually overlapping) disks is ground on the surface. This is a traditional horological finishing technique. It is also sometimes found on decorated automotive and aircraft components (most famously Lindbergh's "Spirit of Saint Louis.") Although the finish it produces is lovely, its original purpose in horological use was as a relatively cheap way to produce a good-looking surface without the expense of actually polishing it.

Spotting is now frequently, though incorrectly, called "engine turning." See a discussion of the difference between Engine Turning and Spotting .

I have examples from current work in the mass-market end of the Chinese mechanical watchmaking industry of a finish that is almost certainly intended to imitate spotting which is produced not abrasively but, I believe, with a multi-point cutting tool. While historically spotting has always been a distinctively abrasive process, because this technique is so clearly intended to imitate spotting I'll cover it here.

Imitation spotting (usually under the name of "engine turning") has since at least the 1970s been available in plastic applique form. Since this isn't really a surface finishing technique but rather a form of wallpaper for machines, I won't cover it here.

"Spotting" is the term most often encountered in the traditional horological literature in English.

Also called "stippling." See Sermier, Caroline and Giulio Papi. High-End Horological Finishing and Decoration. (Le Locle, CH: Audemars Piguet, 2006): 98.

Also called "perlée". See http://en.wikipedia.com/wiki/Perlée

Also called "Perlage" See the A. Lange & Sohne web page at http://www.alange-soehne.com/cms/en/manufactory/superb-craftsmanship/artistic-decorations.html.

In German, probably "perlschliff". See http://de.wikipedia.com/wiki/Perlschliff

I think, but am not completely certain, that this is also what is termed "circular snailing" by Claudius Saunier in Watchmakers' Handbook, trans. Julien Tripplin and Edward Rigg (London: J. Tripplin, 1882; reprinted): section 174.

In Connelly's book Machine Tool Reconditioning (see below) what is clearly described as spotting is called "circular flaking." However, as Connolly holds this method in low esteem, the spotting enthusiast might prefer to ignore this synonym.

This may be the most famous example of spotting - the engine cowl of Charles Lindbergh's "Spirit of Saint Louis." This photograph is from the US Library of Congress Prints & Photographs Division website. Published circa 1927. Copyright not renewed; public domain. Source: http://www.loc.gov/pictures/item/2002721494/

Above left is a photograph of the "semi-manual" application of spotting ("perlage") to a watch movement. Above right is a different watch movement on which spotting (again, "perlage") has been done manually. Both photographs are from Wikimedia Commons and were uploaded by user "Watchexpert." Both have been placed by that user in the public domain. Locations: http://commons.wikimedia.org/wiki/File:Perlage_03.JPG http://commons.wikimedia.org/wiki/File:Perlage_01.JPG

Above is a photograph of a watch movement to which spotting ("perlage") has been applied "semi-manually". The photograph is from Wikimedia Commons and was uploaded by user "Watchexpert. It has been placed by that user in the public domain. Location: http://commons.wikimedia.org/wiki/File:Perlage_02.JPG

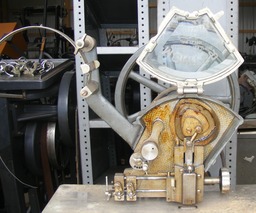

On the left is a Latham Monitor No. 1 1/2 Wire Stitcher manufactured near the turn of the 20th century (though the spotted finish may date from its rebuilding in the 1940s). The finish can be seen best in the full-resolution version of the photograph; click for that, and perhaps click again for the full-resolution view if your browser auto-shrinks images. On the right is the inside of a watch case, showing spotting applied in a non-rectilinear pattern.

The photograph on the left is by the author, of a machine in my possession. The photograph of the watch case on the right is from Wikimedia Commons; it is by Hans Becker and has been released by him into the public domain. Location: http://commons.wikimedia.org/wiki/File:Spotting_Zierschliff.jpg)

Above aere are two examples of spotting as applied to automobiles - perhaps its most popular application outside of horology. Both are of Bugatti engine compartments. The one on the left is of a 1938 Bugatti Type 57SC Atlantic Coupe. The one on the right is of a 1937 Bugatti Type 37A. Note, however, that in both images two different kinds of surface finishes are shown. The firewalls of each Bugatti are spotted, but the actual engines are not. They are Flaked (a variety of hand scraping). See the Notebook on Engine Turning vs. Spotting for a further discussion of this and links to the Bugatti literature (including references to articles by Phillips and Leydon in Pur Sang).

Both images are from Wikimedia Commons. The one of the Type 57SC is by user Sfoskett and is of a vehicle in the Ralph Lauren collection on display at the Boston Museum of Fine Arts in 2005. License: GFDL or CC By-SA 3.0 Unported. Location: https://commons.wikimedia.org/wiki/File:RL_1938_Bugatti_57SC_Atlantic_engine.jpg. The one of the Type 37A is by user Liftarn and is of a vehicle at the Prins Bertil Memorial in Stockholm, Sweden. License: GFDL or CC By-SA 3.0 Unported. Location: https://commons.wikimedia.org/wiki/File:Bugattiengine.JPG

A photograph in Cars and Motor-Cycles edited by Lord Montagu of Beaulieu and Marcus W. Bourdon (1928) clearly shows spotting as applied to the crankcase of an eight-cylinder supercharged Delage automobile engine. (A scan of this image is online on Wikimedia Commons, as it is in the public domain in England. Regrettably, it is now in copyright in the US and I cannot reprint it here.)

Above is a 1940 Buick Super Convertible Coupe, beautifully restored. It appeared originally on flickr in the photostream of R. B. Boyer ( http://www.flickr.com/photos/31536375@N00/30644204; as he was kind enough to license it under the Creative Commons Attribution-ShareAlike 2.0 Generic license, it has since been mirrored on Wikimedia Commons, location: https://commons.wikimedia.org/wiki/File:1940_Buick_Super_Convertible_Coupe.jpg) Boyer notes that in the restoration of this automobile, his father "engine-turned the dashboards." The dashboard panels are, however, spotted, not engine-turned.

Spotting can also be done with the end of a tube rather than the end of a solid dowel. [rec.crafts.metalworking FAQ calls this "jeweling," but I have as yet no authoritative reference for this process variation or term.]

Spotting is (relatively) well covered in the traditional technical horological literature.

Here are a number of references, particularly early references, mostly from the popular mechanical and home shop literature.

Tarr, Philip R. "'Engine-Turned' Finish on Metal Made in Your Drill Press." Popular Mechanics, Vol. 68, No. 1 (July, 1937): 134.

A brief note which describes the process of abrasive spotting (calling it "The decorative effect, which is known as 'engine-turned' finish") using an abrasive pad (or steel wool) on a drill press. (This issue of Popular Mechanics is viewable online via Google Books, but is in copyright so I cannot reprint it here.)

Wallin, Herman R. "Decorative Covers Dress Up Cigarette Boxes." Popular Mechanics. Vol. 81, No. 3 (March, 1944): 97. [Online via Google Books]

Wallin calls spotting "engine finish."

As discussed in the Notebook on the difference between Engine Turning and Spotting , this article is rather confused in some respects. It does, though, give a procedure for spotting on the drill press. It also discusses a range of other techniques.

Burton, Walter E. "The Finishing Touch: Skin-Deep Beauty May Make or Mar Your Metal Projects." Popular Science, Vol. 146, No. 5 (May, 1945), pp. 181-185.

Shulze, R. Burt. Aluminum and Magnesium Design and Fabrication. (McGraw-Hill, 1949): 559.

[The "snippet" view on Google Books reveals "End brushes, with wires parallel to the axis of rotation, may be used to produce the series of overlapping circular patterns sometimes called 'engine finish.' This may be varied by using brushes of different diameters. An engine finish may also..."]

1955. Birdsall

Birdsall, George W. Do It Yourself with Aluminum: 125 Projects for the Home Craftsman. (McGraw-Hill: 1955): 38. This is a rather nice book on aluminum fabrication projects for the nonmachinist. It describes spotting (which it calls "Damascene or watch-case finish ... also known as an engine finish or a sun-swirl finish" (but never "engine turning"). It also illustrates a simple jig for producing it using a power hand drill.

The icon here links to a PDF of my scan of this page from the original.

Edward F. Connelly's book Machine Tool Reconditioning (St. Paul, MN: Machine Tool Publications, 1955) is still in print and remains the basic, comprehensive, text on rebuilding machine tools using functional "hand scraping" techniques. In it, he also devotes a chapter to the distinct but related decorative hand scraping techniques of frosting, butterfly frosting, and flaking. These are all cutting processes employing the hand scraper (an edge tool); they are not abrasive processes.

In a brief section (pp. 173-174) he also discusses what is clearly the technique of spotting (using abrasives). He calls it "circular flaking," which is a term for it that I have not encountered elsewhere. He does not, however, hold this process in high esteem:

"This type of flaking mark, however, is never found on a piece of high grade machinery. Essentially, it distinguishes the handicraft of the home workshop enthusiast."

Most modern sources do not mention it, but Eric B. Gent, writing in a signed entry in Alan Smith, Ed. The International Dictionary of Clocks (NY: Exeter Books, 1984): p. 184 describes the finish produced by abrasive polishing with Water of Ayr stone paste as a "grey" finish produced to prepare a surface for spotting (and other finishes).

Prof. Eamonn Keogh has a page devoted to his extremely nice spotting work. He calls it "Engine Turning" because that was the term commonly used in the 1990s in the automobile restoration community when he learned this art. He does, though, distinguish it from "the other kind of Engine Turning." See: http://www.cs.ucr.edu/~eamonn/et/et.htm

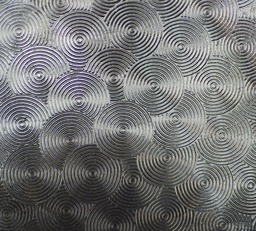

In the mass-market segment of the mechanical watchmaking industry in China, a form of imitation spotting is now used in some watchcase finishing. The overall patterns are the same as those of actual spotting, but closer inspection reveals a regularity of pattern within each spot which is unlike that produced by abrasives. The lines within each spot are perfectly concentric circles. I believe that this finish must be produced through the use of a cutting tool (probably a multi-point cutting tool). It is therefore a sort of "simplest possible" case of engine turning (a cut geometrical pattern; in this case one composed of circles). It isn't quite the same thing as grailing, which would have a single pattern of concentric circles on the entire watchcase.

(I do not know for certain the method used to produce this finish. It is possible that it might be produced by stamping. But if it were stamped rather than directly cut one would guess that the die would have been made with a certain care, and one would not expect to see the variations in the circles both within each spot and in the placing/overlapping of the spots relative to each other.)

This process differs from spotting in another respect: it is not actually the final finish. After this "imitation spotting" is cut into the metal of the case, the case as a whole is plated. True spotting, by way of contrast, was always a final finish (barring any clear lacquers or the like to protect it, of course).

Those who delight in irony will note that while the historically inaccurate use of the term "engine turning" to mean spotting evolved out of the use of spotting to provide a "simulated engine-turned finish" this is the use of a very simple form of engine turning to simulate spotting.

If indeed this finish is produced by a multi-point tool, then that is further distinctive because the use of multi-point cutting tools for finishing is historically quite rare (I cannot think of an example at present, though I'm sure it must have been done). While I do not know for certain that a multi-point tool is being used, the way in which the imperfections in some of the rings line up is quite suggestive (I would assume that if this were a CNC single-point cutting tool that these imperfections would be radial, but here they are skewed):

No doubt horological purists would scoff at such a finish, but I do not. Spotting itself was introduced as a measure of economy - a way to obliterate or disguise surface blemishes without going to the full expense of polishing a piece. This "imitation spotting" simply takes this process a step further. The surface it produces, while certainly more brash and less refined than traditional spotting, is not displeasing. Moreover, it is clear from an analysis of the costs involved that the production cost of this finishing step must be pennies. It is not traditional fine or "haute" horology, but it is a triumph of production engineering.

The photograph of Charles Lindbergh from the Library of Congress reproduced here is in the public domain.

The images by Wikimedia Commons user "Watchexpert" reproduced here are in the public domain.

The photograph of the interior of a watch case, by Hans Becker, is in the public domain.

The photographs of the Type 57SC and Type 37A Bugatti automobiles are licensed under the GNU Free Documentation License or the Creative Commons Attribution-ShareAlike 3.0 Unported license.

Birdsall's Do It Yourself with Aluminum is in the public domain due to failure to renew copyright as then required. The extract reprinted here remains in the public domain.

The photograph of the 1940 Buick Super Convertible Coupe by R. B. Boyer is licensed under the Creative Commons Attribution-ShareAlike 2.0 Generic license.

All portions of this document not noted otherwise are Copyright © 2012 by David M. MacMillan and Rollande Krandall.

Circuitous Root is a Registered Trademark of David M. MacMillan and Rollande Krandall.

This work is licensed under the Creative Commons "Attribution - ShareAlike" license. See http://creativecommons.org/licenses/by-sa/3.0/ for its terms.

Presented originally by Circuitous Root®

Select Resolution: 0 [other resolutions temporarily disabled due to lack of disk space]