This is a short overview of the major developments in machines to cast letterpress printing types for hand setting.

The prerequisite developments necessary for the first commercially successful typecasting machine ( Bruce's "pivotal" type caster) were:

Additionally, the choker valve appears on many (but not all) typecasting machines.

The typefounders' hand mold dates to the 15th century. Aside from details of construction which do not affect the principles of its operation it remained unchanged until the 19th century. 1

At some point around 1805, Edwin Starr at Elihu White's Type Foundry (New York) commenced making hand molds of hardened steel . 2 Through his broad influence, this became standard American practice.

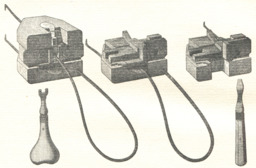

Soon after that, the lever hand mold changed the nature of hand casting, and greatly increased its speed. The matrix handling mechanism of the lever hand mold became the model of the matrix handling mechanism of Bruce's pivotal type caster. The lever hand mold was invented twice, nearly simultaneously. Both forms accomplished the same movements of the matrix but employed different mechanisms. Its first invention, by John Peek in England in 1809, does not appear to have seen wide use. Its second invention, by Archibald Binny in America in 1811, seems to have been widely adopted, and was used internationally. It was the style which prefigured the matrix equipment of the pivotal caster. 3

The first attempt at a typecasting machine was by Elihu White and William Wing (in the US) during the decade leading up to their 1805 patents. It was not successful.

The first typecasting machine manufactured in some quantity and used in type foundries was Mann & Sturdevant's of 1831 (in the US). But it was used only in foundries associated with its financial backer (Elihu White) and was abandoned soon after the invention of Bruce's pivotal type caster.

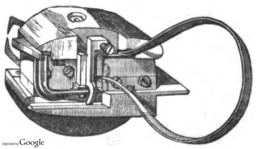

The first commercially successful typecasting machine was Bruce's pivotal type caster (in the US). Although the pivotal type caster, like any invention, had several prerequisite developments, Bruce's synthesis of them and his introduction of the caster's unusual pivoting motion was completely novel. His first version, which saw only very limited use, was patented in 1838. 4 His second version of 1843 (with the addition of a nozzle plate in 1845) continued in one form or another in commercial operation until the first years of the 21st century. It ranks as one of the great inventions in technological history.

For the most part, type foundries constructed pivotal casters (or had them constructed) for their own use. (This was especially true in the United States.) Consequently, there was a great deal of variation between machines. There is no such thing as a "standard" pivotal caster. In the late 19th and early 20th centuries, some type foundries and typefounders' suppliers began manufacturing pivotal casters for sale. Examples include Wood, Miles & Co. and the Williams Engineering Company (Nodis Works) in England and Morikawa Ryobundo in Japan.

Note on the influence of technology on art: The introduction of the pivotal type caster was not simply a back-room technical achievement. It was one of three nearly simultaneous developments 5 which enabled the characteristically complex ornamental display types of the 19th century.

The pivotal type caster, like the hand mold before it, produces unfinished type which must then undergo several manual "dressing" operations:

From the 1840s through the late 1870s there were several interesting machines, including some in commercial production. At least one of these machines produced fully dressed type. The choker valve was also invented during this period ( 1849, by Sturgis in the US), and was adopted on many type casting machines.

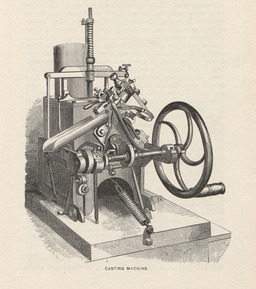

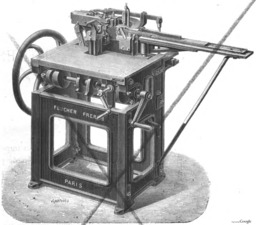

It was not until the Foucher type caster of 1878 in France, however, that a commercially successful machine producing fully dressed types appeared. The Foucher differed from the pivotal type caster in almost every respect. Its mold did not pivot, of course. It produced fully dressed type, and thus had a relatively complex path for type "delivery" (vs. a simple chute for the pivotal). It was not built by a type foundry, but was created by a typefounders' supplier and manufactured for sale to type foundries. 8 In all of these ways it established what became the dominant practices in type casting machine design.

The Foucher, in various models, remained in production well into the 20th century. "System Foucher" machines were produced in Germany by Küstermann in Germany (the Küco-Vital "KV" series of machines of the 1950s and 1960s were late descendents) and in China in the 1930s by the Jianye and Ruitai companies of Shanghai. The Foucher was also the basis for the Barth Type Caster of the late 1880s in America. 9 Taken all together, these machines indicate that the Foucher was second only to the pivotal type caster in its longevity and influence.

Note on terminology Machines such as the Foucher which produce fully dressed types are often called " automatic" casters in the US, but this term isn't really accurate (as any caster operator will tell you, there's nothing "automatic" about typecasting). The equivalent German term, " komplettgießmaschine" (complete type casting machine), is much more descriptive.

The next important machine came from a different kind of source. The Monotype Composition Caster became commercially viable around 1900. While in principle one could punch a tape instructing the Composition Caster to cast a font of type, that wasn't really what it was intended for (and it would be limited to text sizes only).

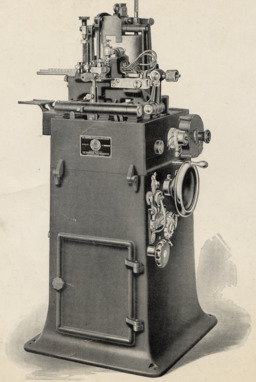

But in 1904 Lanston Monotype introduced auxilary "equipments" for this machine which suited it for casting type for the cases up to 36 point. Referring to this machine is difficult for both technical and marketing reasons. On the technical side, the amazing compatibility of Monotype engineering allowed one to convert this machine from composition to "sorts" casting and back again. On the marketing side, Monotype did a remarkably bad job at naming this machine. The name that finally became most widely attached to a slightly later version was the " Type-&-Rule Caster." 10 This machine continued in production until the demise of the Lanston Monotype Machine Company (US) in 1970 and the later end of The Monotype Corporation Limited (UK) as a hot metal company. Examples are still in use today. The massive production of matrices for this machine, in sizes from 14 to 36 point, was the mainstay of commercial typefounding in the United States throughout the 20th century (and remains so today).

The provision of "sorts casting" capabilities for the Monotype was a part of a larger phase of collective insanity which gripped the type machine community in the first decade of the 20th century. This was the notion of "Every Printer His Own Typefounder." 11 It was a crazy idea because printing and typefounding are very different activities, and most printers don't want to be typefounders. This notion didn't last, but over a period of nearly a decade it produced several important typecasting machines. Rather than outfitting the typical printing shop, some of these became the standard machines which enabled the independent type founding industry in America. 12 In addition to the Monotype Type-&-Rule Caster, these included the Compositype (1899), which did not fare well and the Nuernberger-Rettig (1906), which did a bit better. The latter was a pivotal type caster with a more elaborate drive mechanism and an optional special mold which eliminated the need to plow the groove in the type.

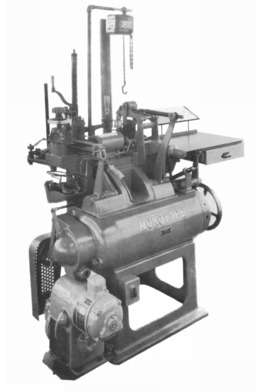

But without question the most important result of this otherwise misguided movement, and one of the most important type casting machines of all time, was the Thompson Type Caster. The Thompson is a machine of great versatility and astonishing simplicity. Suitably equipped, it can cast from matrices intended for many other machines (Linotype, Type-&-Rule Caster, Ludlow, etc.) It was also relatively inexpensive, when compared to other machines. Time has shown that it can also be coaxed to produce good type even when worn to a degree which might have shocked its original builders. Its primary limitation is that it can cast type no larger than 48 point. It also trims only two, not four, sides of the type. 13

The Thompson was produced by the Thompson Type Machine Company from 1907 to 1929 (primarily in Chicago). The Thompson company was then purchased by the Lanston Monotype Machine Company and production was moved to the Lanston factory in Philadelphia. It was produced in America until 1967, 14 and slightly later by The Monotype Corporation Limited in England. But the Thompson also influenced other machines, particularly in Asia. Thompson copies were produced after 1913 by the machine shop of The Commercial Press in Shanghai, and as late as 1940 by the Chong Shing company, also in Shanghai. 15 Direct copies of the Thompson appeared in Japan from 1918, but after the Second World War a more important development occurred. The Koike Manufacturing Company developed the Koike Automatic Type Caster. 16 This was an improved Thompson which featured trimming of all four sides of the type (though this trimming apparatus was designed for fixed-set-width Asian type) and, optionally, matrix changing magazines.

Nobody seems quite sure why Lanston Monotype purchased the Thompson firm in 1929, since by that time the Thompson overlapped with one of their own products. In 1923, to bypass the 36 point maximum size limit of the Type-&-Rule Caster, they introduced the Lanston Monotype Giant Caster. It was called this not because of its size as a machine, but because it could cast type up to 72 point. Mauritz Indahl was the engineer in charge of its design.

The Giant Caster was a machine of the same general class as the English Monotype firm's Super Caster (see below), but due to territorial arrangements the Giant Caster was the only one of the two machines sold officially in the United States until the demise of the Lanston firm in 1970, and it was not exported overseas.

The next important development in typecasters happened on the other side of the world and is as yet largely unrecognized in the West. It started in 1915, with the development by 杉本京太 (SUGIMOTO Kyōta) of the first Japanese-language (that is, 邦文, Hōbun) typewriter. This typewriter required a typecasting machine to produce its types. This caster was developed by about 1917. The Sugimoto typewriter was successful, and the comany which made it, 日本タイプライター株式会社 (Nihon taipuraitā kabushikigaisha, Nippon Typewriter Co., Ltd.), later became part of the Canon company. In the early 1920s, one of the people involved in this effort, 林栄三 (HAYASHI Eizō) founded a separate company (known by 1926 as 林栄社, Rin.Ei-Sha, or more simply on the caster nameplates, RINEISHA). Together with his chief engineer 物部延太郎 (MONOBE Nobutaro) they introduced in 1926 a new type caster, the 万年, or Man-Nen ("Million Year" - more formally 万年活字鋳造機, Man nen katsuji chūzō ki, "Million Year Type Casting Machine"). Like the Foucher and Barth, the Man-Nen is a "complete" or "automatic" machine which produces fully finished type. But its method of doing so - and in particular its type delivery path - is entirely different.

Unfortunately, even some Japanese writers on type appear to view the Man-Nen as nothing more than a modified Thompson. This is, most emphatically, not so. While I have only been able to study the Man-Nen via photographs and video, I do know the Thompson pretty well - and I can assure you that the Man-Nen is in no way a Thompson derivative. It is a an original design, and it stands alongside the pivotal, Foucher, Thompson, etc. as one of the primary original, and successful, caster designs.

It was also an influential design. In Japan, it provided the basis for the postwar Hakko Type Caster. (The pre-war Man-Nen has an interesting type delivery path which rotates the type 90 degrees for trimming. 17 The Hakko, while generally similar to the Man-Nen, has a straight delivery path and employs a reciprocating knife unit for vertical trimming.) The Hakko in turn was copied (as, e.g., the Takwan in Taiwan). In the People's Republic of China, the Man-Nen was copied more directly both in the ZD-201 (and perhaps other casters in the ZD range) and the Hefengyong. 18

For our last major development, we go back to England before WWII. The Monotype Corporation Limited (that is, the English Monotype firm) introduced their own type casting machine in 1928: the Super Caster. Rich Hopkins says of it: "This machine, with proper attachments, was truly a type foundry within itself, capable of casting type from 4 point through 72 point, plus an extensive variety of furniture, leads, slugs, and strip rule of all descriptions." It was produced until 1978. 19 A well-maintained Super Caster is probably about as close to "automatic" as typefounding is ever going to get.

Here's a chart summarizing the history of these machines (which also shows some other machines, as well as general developments). Clicking on the (unreadable) image below should bring up the same chart in PDF form.

Typefounding continues today, albeit on a much reduced scale. But new developments in type casting machinery ceased generations ago. The post-WWII period saw the advent of phototypesetting. "Hot metal" composition continued successfully in the face of this, and there were new developments in the Linotype (e.g., the Elektron), Intertype (Monarch), Monotype composition caster (Monomatic and Monomatic II), and composition casting in Asia (e.g., the Monotype derived Koike K.M.T. Automatic Typesetting Machine, Chinese language Monotype derivatives, tape-controlled typecasters in Japan, etc.) There were even developments in manually set linecasting (the Nebitype) and stripcasting (the Universal, the Koike stripcaster).

But the last new type casting machine design in the West was the Monotype Super Caster of 1928, and new production of all Western type casting machines had stopped by the end of the 1970s. The last new design in Asia appears to have been either the Hakko or improved models of the Man-Nen in the 1960s.

Yet type casting continues - and this leads to an interesting conclusion about type casting machinery. Speaking very broadly, there were seven major designs of type casting machines:

Once each of these main types entered production, each continued in production, either in its original form or through derivative machines, until the end of the era in the 1960s or 1970s. 20 This pattern does not occur in other industries. Usually one design succeeds another. The wood and wire biplane, for example, dominated aviation in 1913, but nobody would ever construct this type of aircraft on a commercial scale in the jet age. In type casting machinery, by way of contrast, every successful design remained a successful design.

My own thought on this matter is that nobody ever brought a bad type casting machine into commercial production. They're hard enough to build in the first place. It makes no sense to build anything but the best. They're all good machines; we need to keep them running.

1. The history of the hand mold is (or should be) covered in any good history of type. But it's always good to go to source material. See the CircuitousRoot Notebook on The Literature of the Hand Mold.

2. The hardened steel hand mold was significant because Bruce's pivotal type caster is basically a mechanized hand mold. The temperatures of typecasting are such that a hardened steel mold held in permanent contact with the nozzle of a pot would have its temper drawn unless it was water-cooled (as in later practice). The pivoting action of Bruce's type caster allowed him to use a hardened steel mold without the complexity of a water cooling system.

3. The lever hand mold, with its great increase in rate of production, must have dominated typefounding from its introduction in 1811 until it was superseded by the pivotal caster in the late 1840s. It is mentioned in contemporary sources from as far away as Australia. Yet it has vanished from the historical record. This is because most of what we now think we know about hand molds was written in the early 20th century during a romantic backlash against machine techniques in type making. Even if these practitioners and writers had known about the lever hand mold, it would have been too close to the machine and too far from Gutenberg for their taste.

It is Binny's verrsion of the lever hand mold that is shown in mid-century continental European sources such as Prechtl and Laboulaye

4. This first (1838) version of Bruce's pivotal type caster was pirated by Lauritz Brandt and sold in Europe as his own machine. Through the middle of the 20th century you still sometimes saw pivotals in Europe referred to as Brandt machines.

5. David Bruce Jr. argues, in his memoir later published as History of Typefounding in America, that the introduction of the force pump was an enabling factor in the production both of complex ornamented types and of other complex large types (he was engaged in casting a blackletter face when he first used the force pump for hand casting in the 1830s). See {Bruce 1981}, p. 48.

The second innovation was the introduction, with Thomas Starr's 1845 patent, of a practical method for electroforming matrices from pattern types. Bruce identifies this as an important influence in his 1850 article "Type Founding," written for the Commissioner of Patents. See {Bruce 1850}, p. 401.

The best analysis of the role of both the pivotal caster and matrix electroforming from hand-cut patrices on 19th century typography is Stephen O. Saxe's as-yet unpublished article "The Bruce Pivotal Type Caster and Nineteenth-Century Typography." {Saxe 2013}

The third innovation, again one mentioned by David Bruce Jr., was the introduction of composition rollers in printing. See {Bruce 1981}, p. 48.

6. When you do any casting, you pour in a bit more metal than the minimum required to fill the mold. This extra metal extends outward from the casting, and must be removed. In most casting, this piece is called a "sprue." To a typefounder, it is a "jet."

7. "Flash" is unwanted metal in the casting which forms where there are gaps between the parts of the mold (typically these gaps are between the mold proper and the matrix, and so flash occurs at the shoulder of the type). The term "flash" derives from earlier practice in coining and forging with dies. "Flashing" is the sheet metal that you use on the roof and gutters of your house.

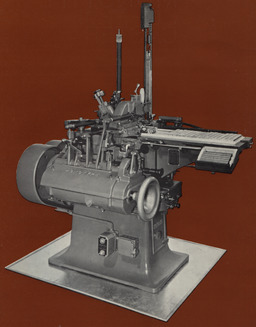

8. After the Foucher, a few type foundries continued to build their own type casters - most notably Stempel in Europe and the Cincinnati Type Foundry / American Type Founders in the US (with the Barth Type Casters). But in general non-pivotal machines of the late 19th and the 20th centuries were built by specialist firms.

9. American printing mythology has since the early 20th century claimed that the Barth was an entirely original design. So for example Huss says "Then in 1888 Hans Barth of the Cincinnati Type Foundry came forth with a new concept in typefounding equipment." {Huss 1973}, p. 13). This is not true. I have a Barth - an extraordinary machine. I've also read the Foucher patents (which predate Barth & Lietze's). In simplest terms, the Barth is a Foucher plus a choker valve. It does not lessen the significance of the Barth to learn of its origins in another machine.

10. So called even when not furnished with rule casting equipment.

11. The phrase is a deliberate echo of the subtitle of Oliver Wendell Holmes, Sr. Autocrat of the Breakfast Table: "Every Man His Own Boswell. It is attested several times in the first decade of the 20th century, though it must be admitted that it seems to have been used mostly by established type foundries in often anonymous articles planted in The Inland Printer and other trade journals attacking these machines. (Examples: "Every Printer His Own Typefounder," Inland Printer Vol. 44, No. 5 (Feb. 1910): 757-758. See also the "Keystone Insert" ("House Organ of the Keystone Type Foundry") in The American Printer Vol 45, No. 2 (Oct. 1907), following p. 164.)

12. By the second decade of the 20th century, "independent" in this sense meant "not American Type Founders." The many small firms comprising this minor industry, equipped with old pivotal casters, Thompsons, Nuernberger-Rettigs, and various Monotype type casters played a far greater role in this history of type in America than has ever been acknowledged. See the CircutiousRoot polemic On the Importance of All Typefoundries.

13. There was a special attachment for the Thompson to trim the other two sides. It appears not to have been popular; none are known to survive.

14. See Richard L. Hopkins, Tolbert Lanston and the Monotype (Tampa, FL: Univ. of Tampa Press, 2012): 80.

15. See {Reed 2004}, pp. 53, 55. "Chong Shing," which advertised using that romanization of its name in 1940, would now be spelled Changxing. My thanks here and elsewhere to Victor Thibout for his knowledg of and assistance with matters of Chinese and Japanese typefounding.

16. Most typefounders in America, at least, are familiar only with this one Koike machine. The Koike firm actually made what might be the wides range of type- and line-casting machinery of any company, including the K.M.T. Automatic Typesetting Machine (a Monotype-style composing type caster with matrix cases of up to 4,992 matrices), an Elrod-derived strip caster, and a version of the Ludlow Typograph.

17. But the Man-Nen shown in Jim Rimmer's article "Typefounding in Vancouver's Chinatown" ( {ATFNL 13} has a straight delivery path. There is much I have yet to learn about these machines.

18. Again I must acknowledge my debt to Victor Thibout for much of my (limited) knowledge of Chinese and Japanese type machinery. The errors here are mine, not his.

19. See {Hopkins 2012}, p. 80.

20. The only exception to this may be the pivotal. It was the first, but I am unaware of any pivotal type caster production after WWII. It may have happened, though.

{ATFNL 13} Rimmer, Jim. "Typefounding in Vancouver's Chinatown." American Typecasting Fellowship Newsletter No. 13 (April 1990): 6-13.

Online in the Notebook on the ATF Newsletter.

{Bruce 1850} Bruce, David, Jr. "Type Founding," in Report of the Commissioner of Patents for the Year 1850. Washington, DC: Office of Printers to the House of Representatives, 1850.

For a reprint of this from Google Books sources, see the CircuitousRoot Notebook on David Bruce Jr.

{Bruce 1981} Bruce, David, Jr., ed. James Eckman. History of Typefounding in the United States. [1874, 1885] NY: The Typophiles, 1981.

See also the CircuitousRoot Notebook "Index to Bruce's History of Typefounding in the United States" .

{Hopkins 2012} Hopkins, Richard L. Tolbert Lanston and the Monotype. Tampa, FL: Univ. of Tampa Press, 2012.

{Huss 1973} Huss, Richard E. The Development of Printers' Mechanical Typesetting Methods, 1822-1925. Charlottesville, Virginia: The University Press of Virginia for the Bibliographical Society of the University of Virginia, 1973.

{Saxe 2013} Saxe, Stephen O. "The Bruce Pivotal Type Caster and Nineteenth-Century Typography." [unpublished article]

The frontispiece, showing a Barth Type Caster in use at the Philadelphia Branch of American Type Founders Company (ex-MacKellar, Smiths & Jordan) by 1896. See: The Barth Type Caster: Images from the Literature.

The typefounder's plain hand mold. From Friedrich Bauer's Das Gießinstrument (1922) , p. 38. It, in turn, reproduces an engraving from Fournier (1764) (Planche V, "Moule à fondres les Lettres").

A Binny-style lever hand mold. From Laboulaye's Dictionnaire (1845)

A mid-19th century pivotal type caster. This cut appeared originally in the Typographic Advertiser (the house organ of L. Johnson & Company, which later became the MacKellar, Smiths and Jordan type foundry). I scanned it from its later appearance in my copy of the 1882 edition of Thomas MacKellar's The American Printer. Yes, this is the image that nearly every 19th century source used. But, having done a pretty comprehensive survey of published images of pivotal type casters, I can attest that there aren't many which are both good illustrations and clearly republishable both in terms of copyright law and contract law.

An early (1886) version of the 1878 Foucher. This is from a catalogue published in 1886 by the company, Foucher Frères. This catalog has been digitized by Google from the Lyon Public Library copy. Here is a local copy of that digitization: foucher-freres-materiel-typographique-1886-google-lyon-public-library.pdf

A System Foucher Küstermann. From Alfred Uhlman's book Der Spritzguß ["Die Casting"] (Berlin: Verlag von. M. Krayn, 1919). This has been digitized by Google. http://google.com/books?id=AMxTAAAAYAAJ

A Barth Type Caster. From the 1912 ATF Specimen Book. See the CircuitousRoot Notebook on American Type Founders for the complete specimen book. See The Barth Type Caster: Images from the Literature for a development of this image.

A Lanston Monotype Type-&-Rule Caster. From a brochure by that company for that caster.

Thompson Type-Caster. From The Thompson: The Quality Type Caster . It shows a Thompson Type Machine Company (that is, pre-Monotype) machine equipped with the Micrometer Set Width Adjustment mechanism and the Stop Motion mechanism.

A Lanston Monotype Machine Company Giant Caster. From "A Giant Caster Plate Book that Never Was," a composite Plate Book for the Giant Caster compiled by Kylian Wrzesinski of Raky Press. Online in the CircuitousRoot Notebook on Monotype Giant Caster Technical Literature.

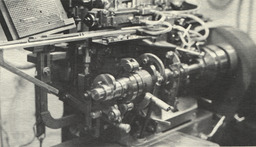

A Rin.Ei-Sha Man-Nen Type Casting Machine (view of the cams). From Jim Rimmer's article "Typefounding in Vancouver's Chinatown" {ATFNL 13}.

A Monotype Corporation Limited Super Caster. From one of the few Lanston Monotype publications on this machine, 'Monotype' Super Caster. Online on the CircuitousRoot Notebook of Sales Literature for the 'Monotype' Super Caster.

All of this illustrations here are in the public domain.

The chart "A Timeline of Type Casting Machine Development" is licensed under the same CC-By-SA 4.0 license as the rest of this Notebook.

All portions of this document not noted otherwise are Copyright © 2015 by David M. MacMillan and Rollande Krandall.

Circuitous Root is a Registered Trademark of David M. MacMillan and Rollande Krandall.

This work is licensed under the Creative Commons "Attribution - ShareAlike" license. See http://creativecommons.org/licenses/by-sa/3.0/ for its terms.

Presented originally by Circuitous Root®